Jun. 28, 2024

1 Listen

When receiving a maintenance request, listen carefully to the phenomenon reflected by the operator. If there are any questions, ask clearly to eliminate the problem caused by human factors.

Listen to the sound of the tool holder operation on site to observe whether there is any abnormal noise.

2 Look

(1) Check whether the tool holder operation process is normal.

(2) Observe the accuracy of the processed parts and the chip marks on the surface of the parts to determine whether the tool holder is locked and whether the repeated positioning is good.

3 Turn

For some faulty tool holders, do not rush to disassemble them. You can turn the tool holder manually. For the four-station tool holder,

there is a 6mm hexagonal hole at the end of the worm.

First remove a sealing screw at this location, and then use a hexagonal wrench or screwdriver to turn the worm to turn and lock the tool holder.

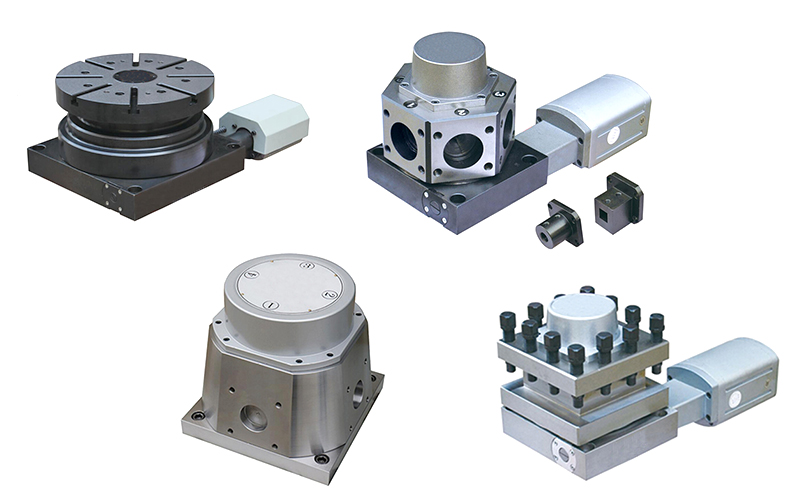

Common causes of tool holder failures and troubleshooting methods

Motor failure

(1) The phase sequence of the three-phase power line is connected in reverse. Troubleshooting method: Immediately cut off the power supply and adjust the phase sequence of the three-phase power supply.

(2) The voltage is too low. Troubleshooting method: Wait until the power supply voltage is normal before using it or add a voltage stabilizer to provide a regulated power supply.

(3) The motor is damaged. Troubleshooting method: Replace the motor.

Previous: Functional analysis of servo turret